Industrial Application Areas

In Indian industry pay huge cost on hard water scale processing, It has been estimated at between 280 to 310 crore annually. The hard problem is very serious in Industry.

As everyone knows, water hardness is due to various dissolved salts, mainly carbonates and sulphates such as those of calcium and magnesium, which when heated produces an insoluble precipitate of scale-forming crystals. Crystals grow by bonding to each other and to water contact surfaces to form scale.

Scale formation affects performance. Just 1mm of scale adds 7.5 % to energy costs, 1.5mm adds 15%, and 12mm demands a staggering 70% cost increase. But the problem of energy costs is only part of the story. There are all the additional problems and maintenance costs of scale removal, anything from inconvenience to total plant shutdowns in severe cases.

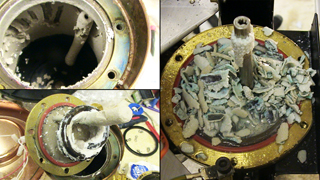

In industry, hard water contributes to scaling in boilers, cooling towers, coils, sprinklers, heat exchangers, washing machines and other industrial equipment. In these industrial settings, water hardness must be constantly monitored to avoid costly breakdowns. Hardness is controlled by addition of chemicals and zeolite resins.

Most companies just build the extra maintenance required to clean the scale off into their schedules and deal with the added expense of the shortened life span of the equipment.

But smart maintenance personnel know there must be a better way - and there is! Tathastu Water softener is best solution....

Features:-:-

- No chemical, No Salt, No Maintenance.

- No wastewater produced,

- No polluting chemicals to drain, No drain line to install.

- No alteration in piping system.

- Reduces existing scales build up

- It consumes very little power to operate.

Benefits:-

- Reduces water heating costs & improve energy management.

- It protects capital equipment from scaling.

- It Increases efficiency of equipment. Water Scaling Problem

- Provide a quick Return On Investment.

- Reduces the Maintenance cycles.

- It can be used for chilled water systems.

- Eliminate the risk of damage to equipment from chemical and mechanical cleaning methods.

Applications:-

Water Heaters:

Calcium normally builds on the bottom of the water heater tank or on the heating coil. It reduces efficiency of the coil. It takes more electric or gas energy to heat same quantity water. The Tathastu water softener unit will dissolve this scale. During the 90-day period. It works more efficiently resulting in huge energy saving. Scale control on heating coil and tank.

Cooling Tower

Tathastu water softener save biocide chemicals, water usage, labor and maintenance .It reducesscale buildup. Biofilm, bacteria, corrosion and algae blooms. It will reduces make up water, resulting in huge water saving. Increase life of equipments and it will lower energy costs by about 17 %. It will allow cooling towers to run at higher cycles of concentration. It extend the life of cooling tower.

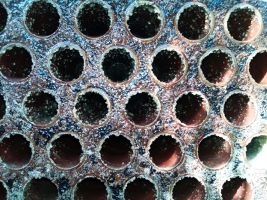

Chillers / Condensers / Air handlers:

Lime scale deposition in heat exchanger tubes and surface of the tube reduce efficiency by almost 7-8 % .As efficiency decreases energy wastage increases. Tathastu water softener removes scale deposition on condenser and chiller tubes. It is direct effect on energy saving. It does not affect the galvanized coating tubes.

It will allow evaporative condenser to run scale free at higher cycles of concentration.

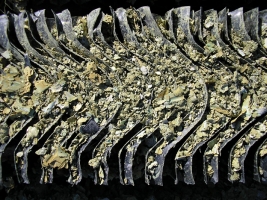

Water Boiler Systems

Hard water also contributes to inefficient and costly operation of water-using appliances. Heated hard water forms a scale of calcium and magnesium minerals (lime scale deposits) that can contribute to the inefficient operation or failure of water-using appliances. Pipes can become clogged with scale that reduces water flow and ultimately requires pipe replacement. Lime scale has been known to increase energy bills by up to 25%. Huge saving in chemicals and labor maintenance. Reduces scale , formation on boiler fire tubes, condensation tank, pumps, pipes and valves. Extends equipments life and lower energy cost.