Working With Electrostatics

In this work , Electrostatic induction spraying with nozzle was proposed and studied experimentally. The purpose of this is to share our experience with people those are interested to understated the behavior of electrostatic field. An electrostatic sprayer is designed and developed to charge the particles which is coming from nozzle. Several parameter create influence on droplet charging such as solution characteristics, physical properties of the nozzle, charging voltage, air flow speed, radius of charging electrode, liquid flow rate and horizontal distance between the electrode and nozzle tip. Induction charging electrode is placed inside the Teflon frame which completely isolated from installation bass. The distance between electrode and nozzle is calculated with the reference of electrostatic field. Most effective variables are nozzle type and size, solution composition, and configuration of the induction electrode.

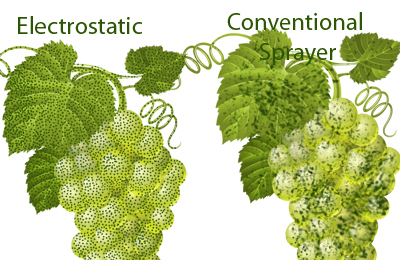

In this system the ring electrode is an agent for charge induction. Sprayers produce small droplets, which are electrically charged as they leave the nozzle. These electrically charge droplets pulls towards the plant is up 60 times greater than the force of gravity. Droplets change direction and move upwards against gravity to coat all of the plant surface. Electrostatic sprayers achieve greater spray droplets. Most of the Agricultural universities, comparing Electrostatics spray with conventional and air-blast sprayers, shows 3.7 times better spray penetration and coverage on hidden areas and dense canopies. Better spray coverage equates to lower chemical consumption. Electrostatic spray is the best solution for the agricultural problems like thrips, aphids, downy mildew, mealybugs, early blight, late blight and listeria.

Benefit Of Electrostatic

Electro statically charged chemical droplets deposit more uniformly on target surfaces. Charged sprays resist overlapping , both in transit and during deposition.

Read More...