We know The nature’s law, Opposite charges attract and same charges repel each other. On this simple phenomenon the electrostatics spraying system works. Tathastu electrostatics is the Tailor-Made solution for existing spraying systems. In conventional spraying system, just addition of electrostatics effect gives all benefit of electrostatics spraying. No need to invest big amount in spray. Because with conventional spray everybody having experience about air pressure, intake liquid, liquid pressure and tractor speed and all other tactics of spraying. In addition of all this everybody having experience with his own spraying unit. Tathastu Electrostatics gives all electrostatic spray benefit with your existing spraying unit.

There are three types charging methods used for electrostatic spraying, including conduction charging, induction charging and corona charging. Among these the induction charging is the most widely used because of the following advantages compared with conduction charging:

Out of the various liquid charging methods, the induction charging approach has appeared to be convenient and practical for the electrification of liquid particle.

Charge Deposition

Improvement

Electro statically charged chemical droplets deposit more uniformly on target surfaces. Charged

sprays resist overlapping , both in transit and during deposition. When all the droplets carry

either a positive or negative charge, uneven movement is reduced because similarly charged

droplets repel one another and retain their original size.

Even size and better quality

fruit

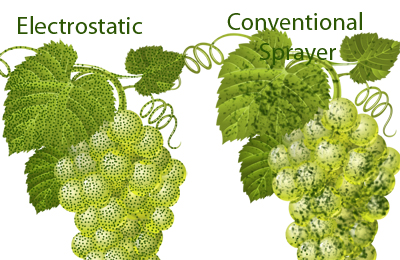

Conventional sprayers create a random mist that covers parts of fruit but not all sides. This

wastes expensive chemicals and severely limits their performance. Electrostatic spray creat

perfectly sized droplets that uniformly cover all sides of the fruit, leaves and vine. The

uniform spray coverage produces a uniform shaped fruit because the complete coverage allows the

chemical to do its job for producing higher quality fruit.

Increase Productivity

Conventional method, spray is not uniform so we didn’t get uniform growth from all sides . but

with Tathastu electrostatic chances off uniform spraying is about 85%. Productivity is also

increased by 30 % than conventional method. And plus side some saving are added like saving of

money because no wastages. less man power. Get better quality.

Improve performance of pesticides,

fertilizer and Other chemical

The electrostatic Spray Systems delivers fertilizers and insecticides to the spaces where they

can work effectively, the size and uniformity of grapes are larger and more consistent.

This Systems allows the chemical reach inside clusters and on the underside of leaves where destructive pests like web spinning spider mites hide. This Systems decreasing the risk of block rot from overly wet fruit.

Environment Saving

The application of pesticide is still one of the most frequently used methods to protect crops

and trees against diseases and insects in agriculture. Over dosage of pesticide is common in

most countries, and its application leads to many problems such as chemical waste and

environmental pollution from spray drift. One of the current trend toward prevention of chemical

waste and environmental pollution is the application of an electrostatic technique in the

agricultural spray.

In this work , Electrostatic induction spraying with nozzle was proposed and studied

experimentally. The purpose of this is to share our experience with people those are interested

to understated the behavior of electrostatic field. An electrostatic sprayer is designed and

developed to charge the particles which is coming from nozzle.

Several parameter create

influence on droplet charging such as solution characteristics, physical properties of the

nozzle, charging voltage, air flow speed, radius of charging electrode, liquid flow rate and

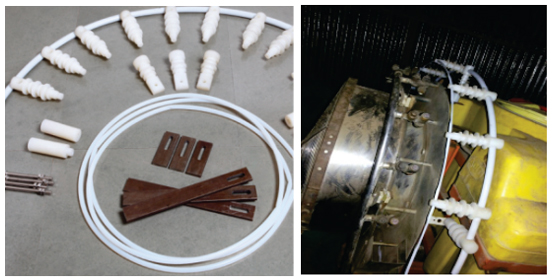

horizontal distance between the electrode and nozzle tip. Induction charging electrode is placed

inside the Teflon frame which completely isolated from installation bass.

The distance

between

electrode and nozzle is calculated with the reference of electrostatic field. Most effective

variables are nozzle type and size, solution composition, and configuration of the induction

electrode.

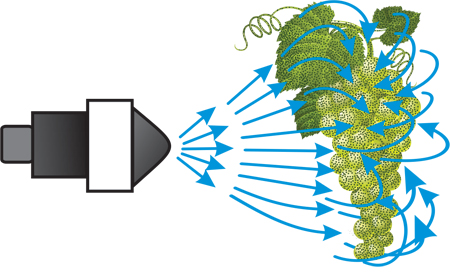

In this system the ring electrode is an agent for charge induction. Sprayers produce small droplets, which are electrically charged as they leave the nozzle. These electrically charge droplets pulls towards the plant is up 60 times greater than the force of gravity. Droplets change direction and move upwards against gravity to coat all of the plant surface. Electrostatic sprayers achieve greater spray droplets. Most of the Agricultural universities, comparing Electrostatics spray with conventional and air-blast sprayers, shows 3.7 times better spray penetration and coverage on hidden areas and dense canopies. Better spray coverage equates to lower chemical consumption. Electrostatic spray is the best solution for the agricultural problems like thrips, aphids, downy mildew, mealybugs, early blight, late blight and listeria.

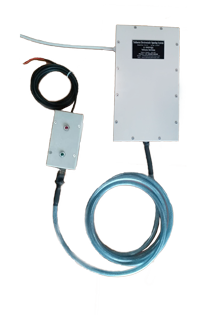

Tathastu electrostatics is the Tailor-Made solution for existing spraying systems. The conventional spraying system has all other thing like air fans, liquid pressure pumps, good quality nozzles and experience with existing system. Tathastu electrostatic use these all things as it is. Tathastu electrostatic having a high voltage generation unit with require power. This unit generate high voltage using nominal 12 volt battery. It has one input, one out put and one control. 12 v use as a input voltage, one out put is control unit and other one is high voltage output.

control unit is use for On/Off the electrostatic induction. The high voltage cable output is connect to the HV electrode. Electrode is design around the nozzle as per customer spraying unit.

Tathastu Electrostatic generate strong induction type electrostatic field around the nozzle. The high voltage electrode assembly is design with precision and experience. High voltage insulator design for very high spraying water environment which will keep isolation between high voltage supply and assembly. In weak isolation voltage will be drop down and induction effect will be less . But in Tathastu electrostatic effect will be constant in all condition.

When water or any spray comes through the nozzle, the high voltage electrode charge the water drop ,with same charge, they repel each other, creating a fine spray mist. On the other side plant having opposite charges, which attract the opposite charge particles drawing from the nozzle. The spray droplet goes deep inside the plant's canopy. One more added advantage is that they never overlap each other. because up to target surface same charge droplet repel each other. The plant is covered fully and uniformly.

Electrical charging of pesticide droplets is a specialist technical domain, the advantages of which are increased spraying efficiency, pesticide deposition on plant targets and reduced drift. The review revealed the benefits of electrostatic charging technology as a means of increasing the deposition characteristics of the spray, and also for bringing many important environmental and cost-saving benefits. It reduces labor cost These all benefits gives fast payback to the user.